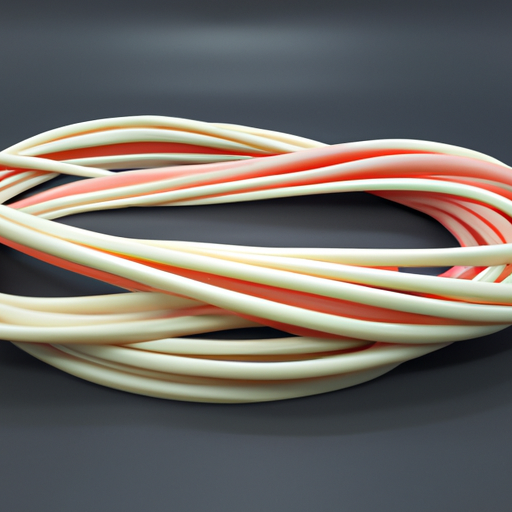

SB-SGS-12 1.2KV Silicone Fiberglass Sleeving: Core Functional Technology and Application Development

**Overview of Fiberglass Sleeving**

Fiberglass sleeving is a specialized insulation material crafted from woven fiberglass strands, often enhanced with silicone or other coatings to improve its performance characteristics. The SB-SGS-12 1.2KV Silicone Fiberglass Sleeving is engineered to deliver exceptional electrical insulation, thermal resistance, and mechanical protection across a variety of demanding applications.

Core Functional Technologies

1. **Electrical Insulation**:

- **High Voltage Resistance**: The SB-SGS-12 sleeving is rated for voltages up to 1.2KV, making it ideal for high-voltage applications. Its robust dielectric strength ensures reliable insulation for sensitive electrical components.

- **Low Electrical Conductivity**: The inherent low electrical conductivity of fiberglass minimizes the risk of short circuits and electrical failures, enhancing overall system reliability.

2. **Thermal Resistance**:

- **High-Temperature Tolerance**: With a silicone coating, the sleeving can operate effectively in high-temperature environments, typically up to 200°C (392°F). This capability is crucial for applications where heat management is essential.

- **Thermal Stability**: The fiberglass base provides excellent thermal stability, allowing the sleeving to maintain its insulating properties across a wide temperature range, ensuring consistent performance.

3. **Mechanical Protection**:

- **Abrasion Resistance**: The woven structure of the fiberglass offers superior resistance to abrasion, safeguarding underlying wires and components from physical wear and tear.

- **Chemical Resistance**: The silicone coating enhances resistance to a variety of chemicals, oils, and solvents, making the sleeving suitable for use in harsh and corrosive environments.

4. **Flexibility and Ease of Application**:

- **Flexible Design**: The sleeving's flexibility allows for easy application to irregular shapes and tight spaces, making it versatile for various installation scenarios.

- **Ease of Installation**: It can be easily cut to length and applied without the need for specialized tools, facilitating quick and efficient installation processes.

Application Development Cases

1. **Automotive Industry**:

- **Wire Harness Protection**: The SB-SGS-12 sleeving is extensively used to insulate and protect wire harnesses in vehicles, ensuring reliable performance in high-temperature and high-vibration environments. Its resistance to oils and chemicals makes it particularly suitable for automotive applications.

2. **Aerospace Applications**:

- **Electrical Insulation in Aircraft**: In aircraft wiring systems, the sleeving provides essential insulation and protection against extreme temperatures and potential mechanical damage, ensuring safety and reliability during flight operations.

3. **Industrial Equipment**:

- **Motor and Generator Insulation**: The SB-SGS-12 sleeving is applied to windings and connections in industrial motors and generators, preventing electrical failures and enhancing durability under operational stresses.

4. **Renewable Energy**:

- **Wind Turbine Wiring**: In wind turbine electrical systems, the sleeving protects wiring from environmental factors, ensuring reliable operation in varying weather conditions and contributing to the efficiency of renewable energy generation.

5. **Consumer Electronics**:

- **Insulation for High-Power Devices**: In high-power consumer electronics, such as power supplies and chargers, the sleeving provides necessary insulation and thermal management, enhancing the safety and longevity of these devices.

Conclusion

The SB-SGS-12 1.2KV Silicone Fiberglass Sleeving stands out as a versatile and effective solution for a wide range of applications requiring electrical insulation, thermal resistance, and mechanical protection. Its advanced properties make it suitable for critical industries such as automotive, aerospace, industrial equipment, renewable energy, and consumer electronics. As technology continues to advance, the development and application of fiberglass sleeving are expected to expand, addressing emerging challenges and enhancing performance across various sectors.