Overview of PTFE, FEP, PFA, and PVDF Tubes

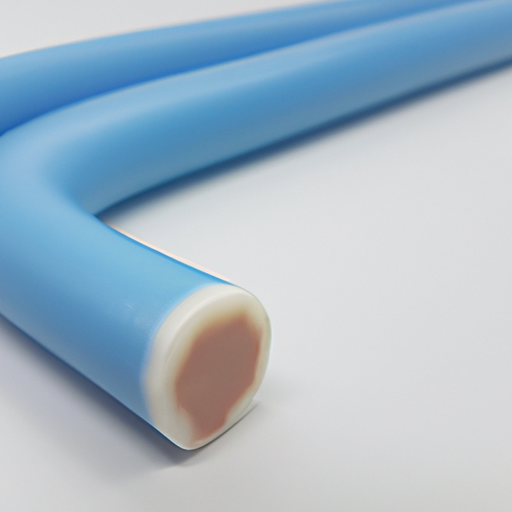

Polytetrafluoroethylene (PTFE), Fluorinated Ethylene Propylene (FEP), Perfluoroalkoxy Alkane (PFA), and Polyvinylidene Fluoride (PVDF) are high-performance fluoropolymer materials recognized for their outstanding chemical resistance, thermal stability, and electrical insulation properties. These materials are extensively utilized in various applications, particularly in industries that demand high-performance tubing solutions.

Core Functional Technologies

| 1. Chemical Resistance | |

| 2. Thermal Stability | |

| 3. Electrical Insulation | |

| 4. Low Friction | |

| 5. Non-stick Properties | |

| 1. Chemical Processing | |

| 2. Pharmaceutical Industry | |

| 3. Food and Beverage | |

| 4. Electrical and Electronics | |

| 5. Aerospace and Defense |

Application Development Cases

Conclusion

The SB-SGS-25 2.5KV silicone fiberglass sleeving, in conjunction with PTFE, FEP, PFA, and PVDF tubes, provides a robust solution for various high-performance applications. The unique properties of these materials make them indispensable in industries such as chemical processing, pharmaceuticals, food and beverage, electronics, and aerospace. As technology progresses, the development of new applications for these materials continues to expand, driving innovation and efficiency across multiple sectors. The combination of these advanced materials ensures that industries can meet the challenges of modern applications while maintaining safety, reliability, and performance.