SBS-SRT-FG PVDF Heat Shrink Tubing: Core Functional Technology and Application Development

Introduction to PVDF Heat Shrink Tubing

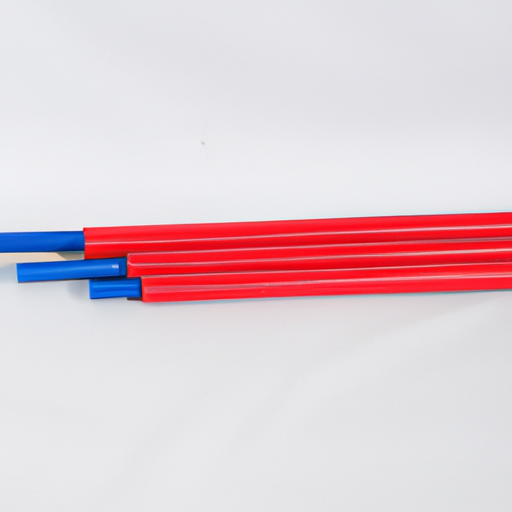

Polyvinylidene fluoride (PVDF) heat shrink tubing is a specialized polymer material known for its excellent chemical resistance, high-temperature stability, and mechanical strength. SBS-SRT-FG is a specific type of PVDF heat shrink tubing that is designed for various industrial applications, particularly in environments where durability and reliability are critical.

Core Functional Technologies

| 1. Heat Shrink Technology | |

| 2. Chemical Resistance | |

| 3. Electrical Insulation | |

| 4. Flame Retardancy | |

| 5. UV Resistance | |

| 1. Aerospace Industry | |

| 2. Automotive Sector | |

| 3. Oil and Gas | |

| 4. Medical Devices | |

| 5. Telecommunications |

Application Development Cases

Conclusion

SBS-SRT-FG PVDF heat shrink tubing represents a versatile and effective solution for a wide range of applications across various industries. Its core functional technologies, including heat shrink capabilities, chemical resistance, electrical insulation, flame retardancy, and UV resistance, make it an ideal choice for demanding environments. As industries continue to evolve, the development and application of PVDF heat shrink tubing will play a crucial role in enhancing the performance and reliability of critical systems.

Future Directions

As technology advances, further research and development in PVDF heat shrink tubing could lead to enhanced properties, such as improved flexibility, lower production costs, and even greater environmental resistance. Innovations in manufacturing processes may also allow for the creation of custom sizes and shapes, catering to specific industry needs. The ongoing demand for high-performance materials in sectors like renewable energy, electric vehicles, and advanced telecommunications will likely drive the continued evolution of PVDF heat shrink tubing applications.