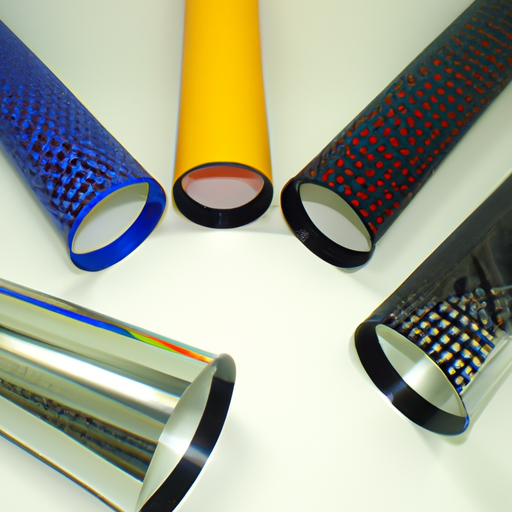

Application Development in Fiberglass Sleeving for SB-TGS-2S Heat-Resistant Thermosetting Tube: Key Technologies and Success Stories

Developing applications for fiberglass sleeving, particularly for high-temperature applications like the SB-TGS-2S heat-resistant thermosetting tube, involves several key technologies and methodologies. Below are critical aspects and success stories related to this field.

Key Technologies

| 1. Material Composition | |

| 2. Manufacturing Processes | |

| 3. Thermal Management | |

| 4. Customization and Design | |

| 1. Aerospace Applications | |

| 2. Automotive Industry | |

| 3. Electrical and Electronics | |

| 4. Industrial Equipment | |

| 5. Renewable Energy |

Success Stories

Conclusion

The development of fiberglass sleeving for high-temperature applications like the SB-TGS-2S thermosetting tube involves a combination of advanced materials, innovative manufacturing processes, and rigorous testing. Success stories across various industries highlight the versatility and effectiveness of fiberglass sleeving in enhancing performance, safety, and reliability in challenging environments. As technology continues to evolve, further advancements in this field are expected, leading to even more applications and improvements in performance.

Future Directions

| Sustainability: Research into bio-based resins and recyclable fiberglass materials could lead to more environmentally friendly products.Sustainability: Research into bio-based resins and recyclable fiberglass materials could lead to more environmentally friendly products. |

| Smart Materials: The integration of sensors within fiberglass sleeving could provide real-time monitoring of temperature and stress, enhancing safety and performance.Smart Materials: The integration of sensors within fiberglass sleeving could provide real-time monitoring of temperature and stress, enhancing safety and performance. |

| Advanced Coatings: Development of nanotechnology-based coatings could further improve the thermal and chemical resistance of fiberglass sleeving, expanding its application range.Advanced Coatings: Development of nanotechnology-based coatings could further improve the thermal and chemical resistance of fiberglass sleeving, expanding its application range. |

By focusing on these areas, the fiberglass sleeving industry can continue to innovate and meet the evolving demands of high-temperature applications.