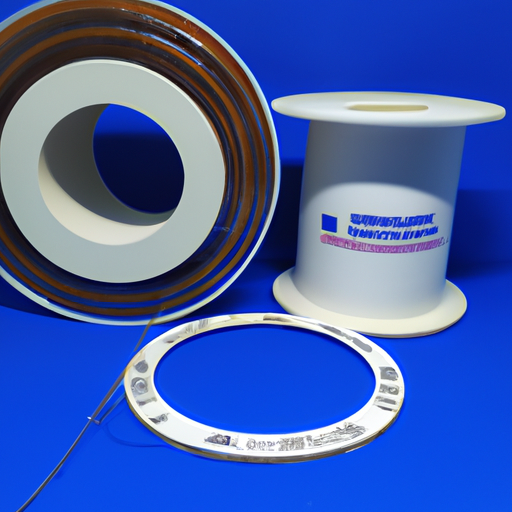

Application Development in High-Temperature-Resistant Special Fiberglass Sleeving: SB-SGS-E Fiberglass High-Adhesion Silicone Rubber Tubing

High-temperature-resistant special fiberglass sleeving, particularly the SB-SGS-E fiberglass high-adhesion silicone rubber tubing, has emerged as a critical material in various industries due to its exceptional properties. This document outlines the key technologies involved in its development and highlights notable success stories that demonstrate its effectiveness across different applications.

Key Technologies

| 1. Material Composition | |

| 2. Manufacturing Techniques | |

| 3. Thermal and Electrical Insulation | |

| 4. Customization | |

| 5. Testing and Certification | |

| 1. Aerospace Industry | |

| 2. Automotive Applications | |

| 3. Industrial Equipment | |

| 4. Renewable Energy | |

| 5. Consumer Electronics |

Success Stories

Conclusion

The development of high-temperature-resistant special fiberglass sleeving, such as SB-SGS-E, marks a significant advancement in materials science, offering innovative solutions across a wide range of industries. Its unique properties and successful applications underscore its importance in enhancing the performance and safety of various systems. As technology continues to evolve, further innovations in this field are anticipated, leading to even more robust and versatile materials that can meet the demands of future applications.