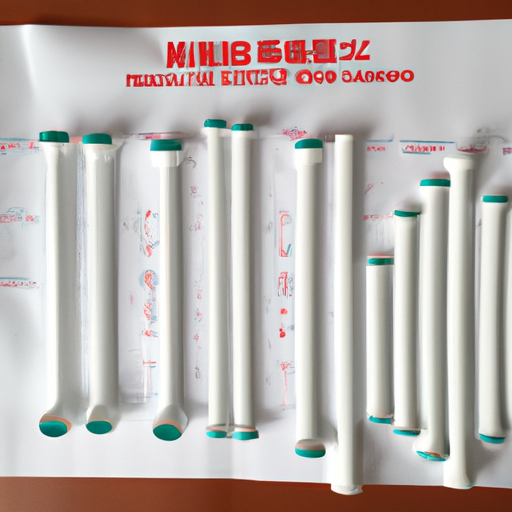

Application Development in PTFE / FEP / PFA / PVDF Tubes for SB-TGS-1050 Quartz Fiber Sleeves: Key Technologies and Success Stories

The integration of PTFE (Polytetrafluoroethylene), FEP (Fluorinated Ethylene Propylene), PFA (Perfluoroalkoxy), and PVDF (Polyvinylidene Fluoride) tubes with SB-TGS-1050 quartz fiber sleeves represents a significant advancement in material science, particularly for applications requiring high chemical resistance, thermal stability, and low friction properties. Below, we delve into the key technologies that facilitate this development and highlight notable success stories across various industries.

Key Technologies

| 1. Material Selection | |

| 2. Manufacturing Techniques | |

| 3. Joining and Assembly | |

| 4. Testing and Quality Control | |

| 5. Customization | |

| 1. Chemical Processing Industry | |

| 2. Pharmaceutical Applications | |

| 3. Semiconductor Manufacturing | |

| 4. Oil and Gas Sector | |

| 5. Environmental Monitoring |

Success Stories

Conclusion

The development of applications using PTFE, FEP, PFA, and PVDF tubes in conjunction with SB-TGS-1050 quartz fiber sleeves highlights the versatility and reliability of these materials across various industries. By leveraging advanced manufacturing techniques, rigorous testing protocols, and customization options, companies can achieve significant improvements in performance, safety, and cost-effectiveness. As industries continue to evolve and demand innovative solutions, the role of these fluoropolymers is expected to expand, leading to further advancements and success stories in application development.