SBD-PVDF-HST PTFE Heat Shrinkable Tubing: Core Functional Technologies and Application Development Cases

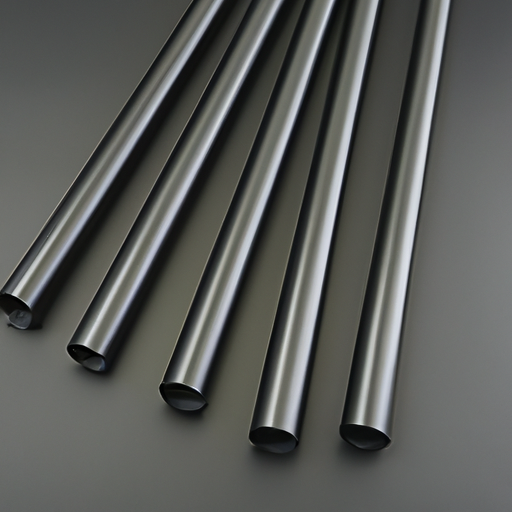

Introduction to PTFE Heat Shrinkable Tubing

PTFE (Polytetrafluoroethylene) heat shrinkable tubing is a specialized material recognized for its exceptional chemical resistance, high-temperature stability, and low friction properties. The SBD-PVDF-HST (Polyvinylidene Fluoride Heat Shrinkable Tubing) variant integrates the advantages of PTFE with the unique characteristics of PVDF, making it suitable for a diverse array of applications across various industries.

Core Functional Technologies

| 1. Chemical Resistance | |

| 2. High-Temperature Stability | |

| 3. Low Friction Coefficient | |

| 4. Electrical Insulation | |

| 5. Shrink Ratio | |

| 6. Non-stick Surface | |

| 1. Aerospace Industry | |

| 2. Medical Devices | |

| 3. Automotive Industry | |

| 4. Telecommunications | |

| 5. Food Processing | |

| 6. Chemical Processing |

Application Development Cases

Conclusion

SBD-PVDF-HST PTFE heat shrinkable tubing offers a unique combination of properties that make it suitable for a wide range of applications across various industries. Its core functional technologies, including chemical resistance, high-temperature stability, and electrical insulation, enable innovative solutions in demanding environments. As industries continue to evolve, the development and application of PTFE heat shrinkable tubing will play a crucial role in enhancing performance, safety, and reliability in numerous applications, paving the way for advancements in technology and materials science.